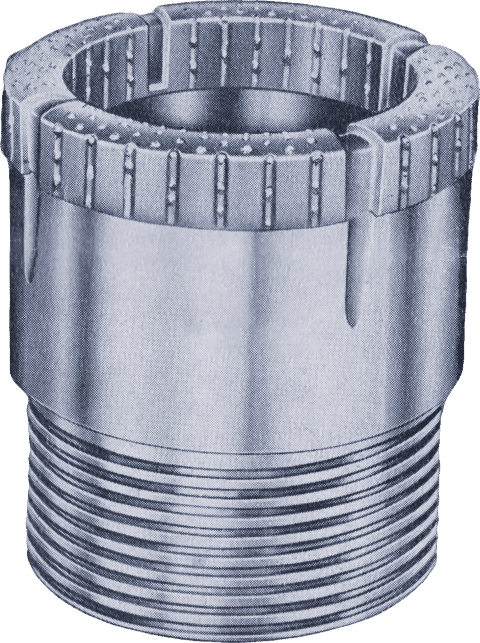

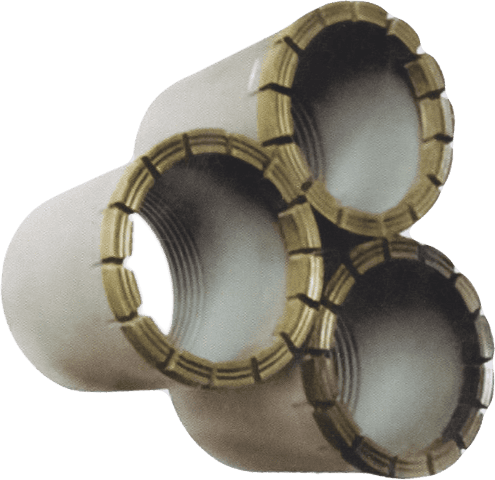

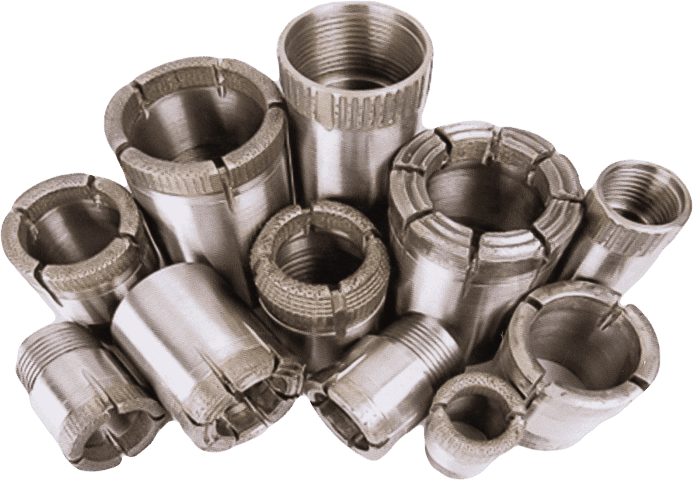

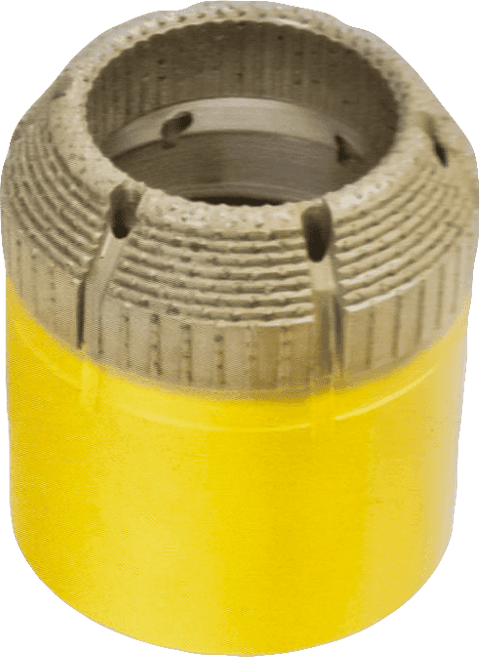

Diamond Core Bits

The economy of a drilling operation depends on the correct selection of a diamond bit for the rock formation to be drilled which will then result in fast drilling speeds, good footage and high salvage value. Detailed studies into the design combination of diamond drill bits are necessary to obtain the best results. With new research in the setting of diamonds, design of watercourses and selection of the proper matrix mix for each type of rock, it is now possible to scientifically select and recommend the right bit for any job.

These main factors have given the proper selection of a diamond bit:

Matrix Combination

The five essential qualities of a good matrix are that it should:

- Hold diamonds firmly in position under all stresses of drilling.

- Be resistant to abrasion so that stones are not rapidly exposed, yet it should not be so hard that fresh stones are not gradually exposed.

- Be capable of absorbing most of the shock load imposed on the diamonds while drilling.

- Have a low sintering temperature to avoid graphitisation of diamonds of high temperatures.

- Dissolve easily in acids to help the recovery of the diamonds for resetting.

Selection of a proper matrix mix is made by taking into consideration the nature of rock formation to be drilled. In abrasive types of formation, a soft matrix tends to wear out fast, overexposing the diamonds to the extent that they either get damaged or fall out of the matrix. On the other hand in drilling hard and solid rocks, if the matrix used is very hard the pressure on the diamonds is excessive and tends to break them. In such rocks, a very hard matrix is recommended but only when the rock has also got abrasive qualities.

Recommended Matrix Hardness

Medium Soft - Normal drilling in formations with little or no abrasion such as solid limestone, sandstone, dolomite, etc.

Medium Hard - Average drilling condition, medium to hard rock, general-purpose, suitable for most rock formations with average abrasive qualities.

Hard - For extremely abrasive and hard rock formations such as granite, quartzite, hematite, gneiss, jasper, chert.

Diamond Grade

In rock formations where diamonds tend to wear out before getting polished, superior grade diamonds BD-1 need to be used to obtain the best results. In rock formations where diamonds tend to break before getting polished or worn, use BD-2 or BD-3 grade diamonds.

Our bits are available in three different grades of diamonds, such grade in as many as nine different stone sizes for surface set bits to cover any types of drilling condition.

Grade Use

Diamond Size

The SPC depends on the formation to be drilled. Smaller stones drill faster as a rule in hard, solid rock but have the disadvantages of breaking when drilling broken formations. Generally the stone size of 60/80 SPC, 80/100 SPC is used for extremely hard solid formations, 30/60 SPC and 40/80 SPC in hard broken solid formations. Larger size diamonds are recommended for use in softer formations.

Each grade of diamond available in different standard sizes ranging from 10/15 SPC to 80/100 SPC for surface set bits. Finer stones are used for impregnated bits.

In soft or sticky formations, large size diamonds are recommended as they can penetrate easily into these formations thus removing more material per revolution and when the formation hardness increase, the number of diamonds need be increased for the following reasons:

- Harder the rock, smaller the size of grain structure and slower the penetration to compensate for this, more and smaller diamonds should be used, which would give more cutting points and better penetration.

- Greater the number of diamonds distributed on the bit, the better is the distribution of pressure on the rock and hard rocks require high pressure to prevent diamond polishing.

Waterways

The function of waterways in a diamond bit is to ensure rapid removal of the cuttings and cooling of the bit. Excessive water flow over the bit crown may cause erosion of the matrix and lift the bit in the hole reducing the drilling rate.

The number and size of waterways is an important design factor and depends on the size and number of diamonds and the type of strata to be drilled. Generally, the more pronounced the waterways, the better is the sludge clearance and less the possibility of blocking off or diamond polishing. Fewer waterways, however, provide much more space for diamond coverage and consequently, the bit has more cutting points.

When drilling in soft formations, it is desirable to have more waterways, say 4 to 6 depending on the size of the bit for quick removal of the sludge and prevention of blocking for harder rocks. However, the number of waterways can be less as there is a need for more diamond cutting points.

To offset matrix wear, the waterways in standard and hard matrix diamond bits are reinforced with tungsten carbide inserts. The reinforced waterways protect the bit face when drilling broken formations as well as the abrasive type of rock, in cases of an extra hard matrix which are abrasive resistant, tungsten carbide inserts are not necessary.

Setting Pattern

Diamond bits must have planed diamond distribution track to hold their gauge, get evenly apportioned wear and ensure prolonged drilling life. This is a combined effort possible with the help of driller discussion with the manufacturer.

Guide for selection of Diamond Bits

| TYPES OF ROCKS | WATERWAYS | STONE SIZE (In s.p.c) | FORMATION |

|---|---|---|---|

| Very Soft | Deep | 6/10 | Massive unbroken like chalk, gypsum, fire clay, etc. |

| Soft | Deep | 10/15 | Coarse-grained, like shale, sandstone, coal. |

| Soft Abrasive | Deep with T.C. Inserts | 10/15 or 15/25 or 15/30 | Abrasive Sandstone |

| Medium Hard | Standard with T.C. Inserts | 25/40 or 30/60 or 40/60 | Hard and slightly broken rock. |

| Hard and Broken | Low with T.C. Inserts | 40/80 or 60/80 | Hard granite, quartz, quartzite. |

| Extremely Hard and Uniform Solid | Low with or without T.C. Inserts | 80/110 | Extremely hard abrasive formations like quartzite hematite, granite, jasper. |

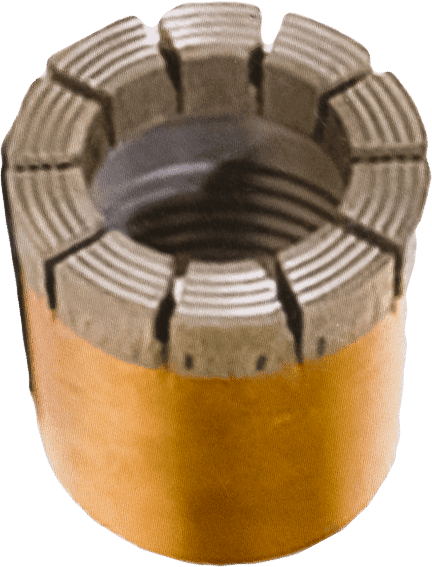

Guide for selection of Impregnated Diamond Bits

| METRIC | CONCENTRATION | RECOMMENDED USE |

|---|---|---|

| NON-ABRASIVE | ||

| Soft | High | Hard, slightly broken formations. |

| Soft | Medium | Solid, consolidated, hard and slightly broken. |

| Soft | Low | Unbroken very hard formations |

| AVERAGE ABRASIVE | ||

| Medium | High | Hard and broken formations. |

| Medium | Medium | Solid, consolidated, hard and slightly broken. |

| Medium | Low | Consolidated solid formations. |

| HIGHLY ABRASIVE | ||

| Hard | High | Hard and extremely broken formations |

| Hard | Medium | Solid, consolidated, hard and slightly broken. |

| Hard | Low | Consolidated solid formations. |

General Drilling Instructions

- Lower the bit only when the hole is clean. Any loose matter will damage the bit.

- Spin the bit slowly for the first few inches. After the bit has settled in increase the feed and speed.

- Ensure correct water circulation before drilling. Stop water circulation only after rock cuttings are removed.

- Use sufficient coolant to avoid burning.

- Check the condition of the bit after every run.

- Retire the bit when it becomes dull or shows signs of matrix wear.

- When penetration rate decreases - sandblast or acid etch the impregnated bits to expose the diamonds.

- Keep the bit at the bottom with sufficient downward pressure.

- Use a diamond reamer shell with the bit when drilling medium hard to hard rock formations.

- Alternate reamer shells when drilling deep holes.

- Do not use wrenches or tongs on the diamond set portion.

- Do not use excessive wrench pressure when coupling bits and shells.

- Recover the core with the use of corepickers - do not run the bit over the core.

- Handle diamond bits carefully - after use clean and replace in the carton provided.

- Use a hydraulic feed drill with a proper pressure gauge.

- Keep the bit from bouncing and vibrating while in operation.